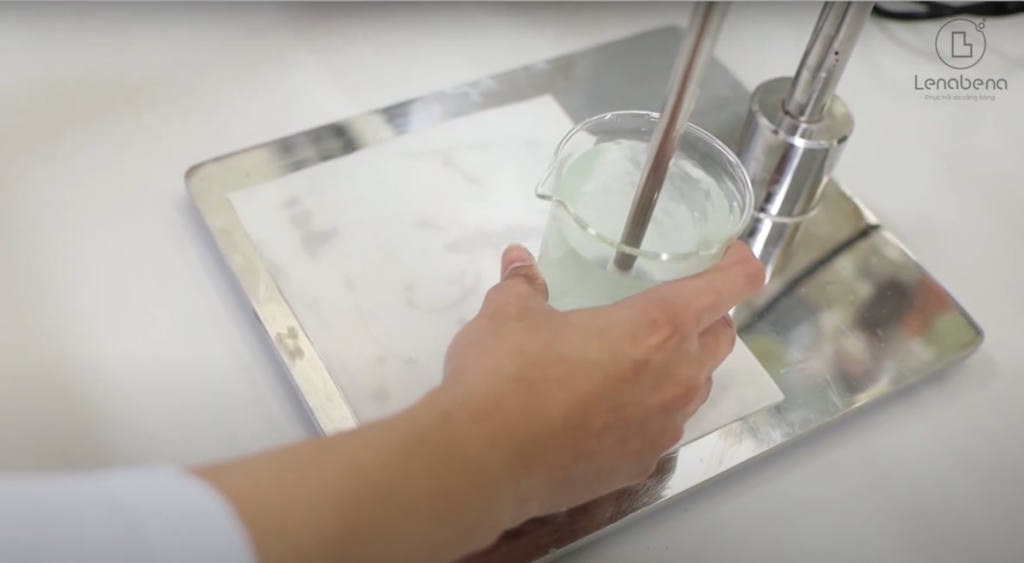

1. First step: prepare cosmetics according to the appropriate process for each product type

2. Check semi-finished products after preparation

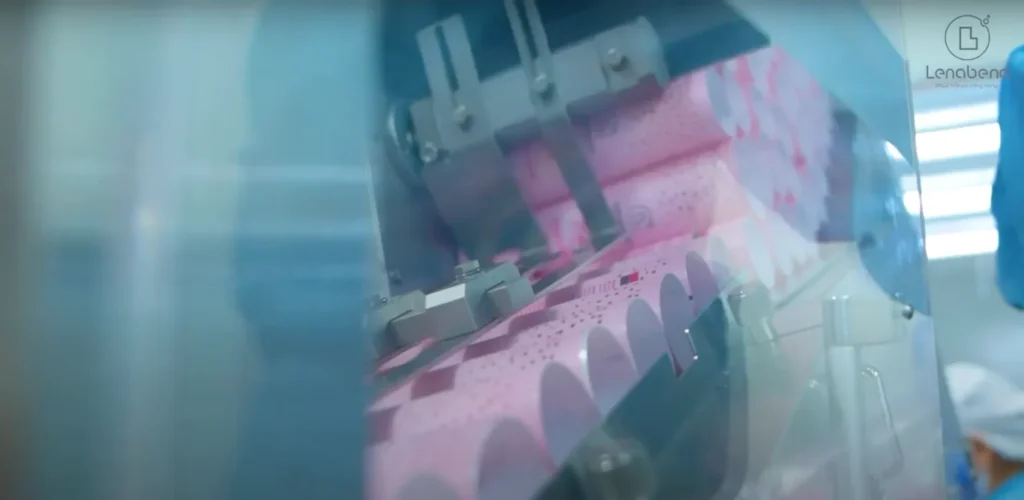

3. Next, put the semi-finished product into the automatic filling equipment

4. The packaging before containing the finished product undergoes careful cleaning to ensure absolute safety for users.

5. Modern machinery system automatically fills the correct volume according to set parameters

6. After that, the product is placed on the automatic conveyor belt to move to the next step, which is to place it on the finished product mass inspection device. Then close the lid tightly to complete the product, printing the date and batch number on the product

7. Finally, the specialist gently puts the cream box into the box, printing the date and batch number on the box

8. Close the lid, stamp, then put it in a neat box and tightly seal it for delivery to the customer